Brazilian rosewood / Douglas Fir MS model

.

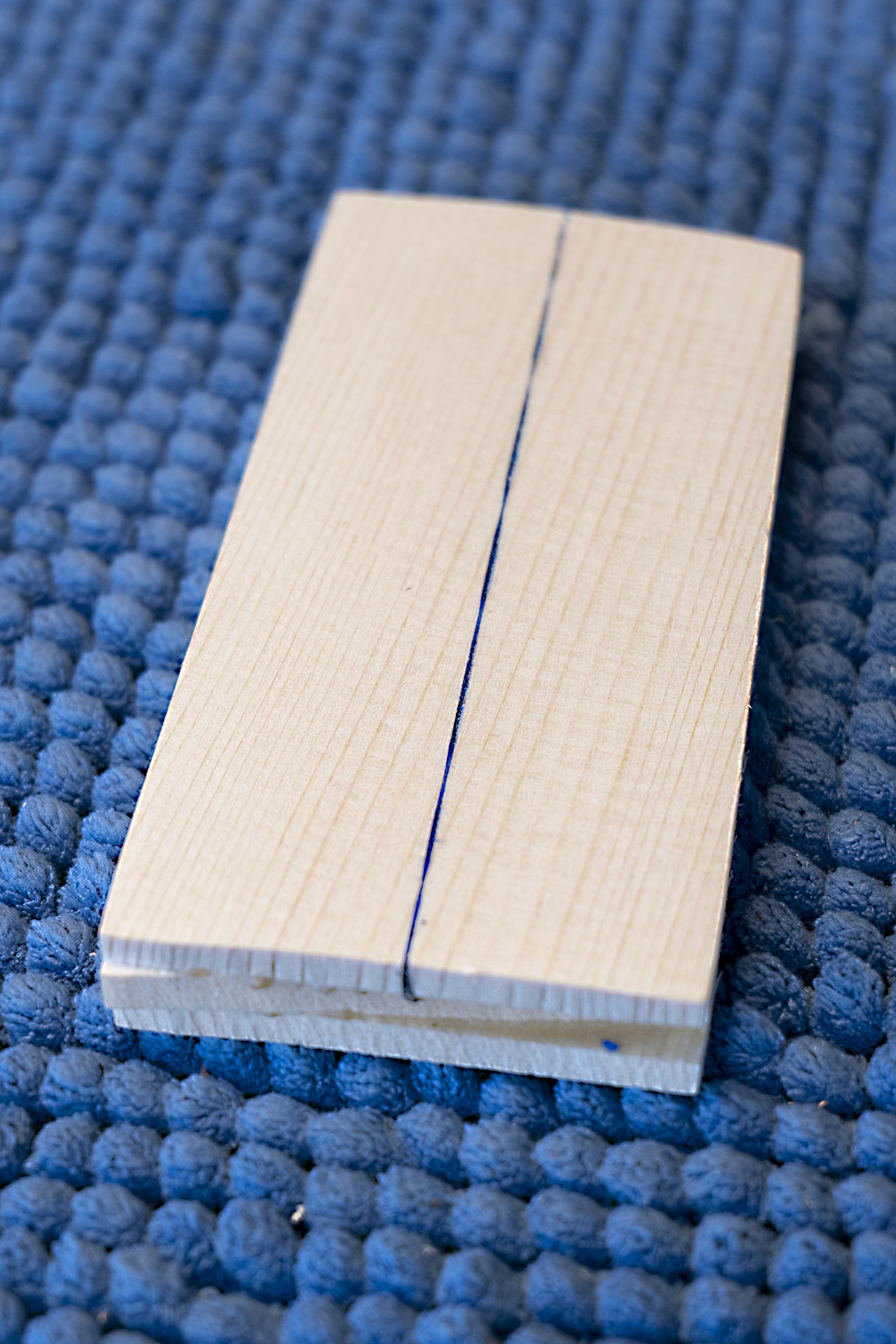

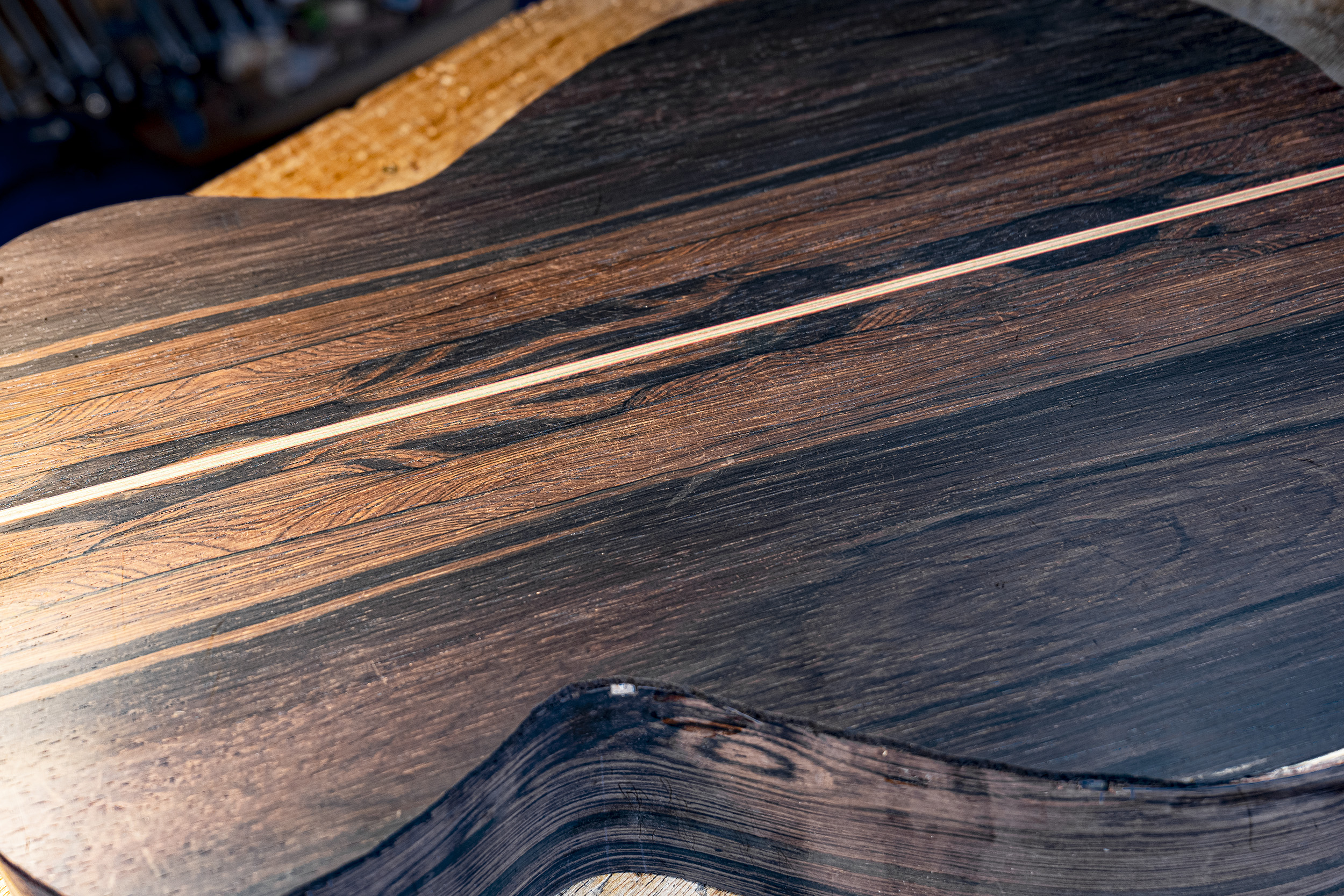

I have started work on a prototype Brazilian rosewood and Douglas Fir Martin Simpson Signature model.

I built a New World Classic (flat soundboard) with a Douglas Fir soundboard which was excellent. This time I’m building to my standard curved top design.

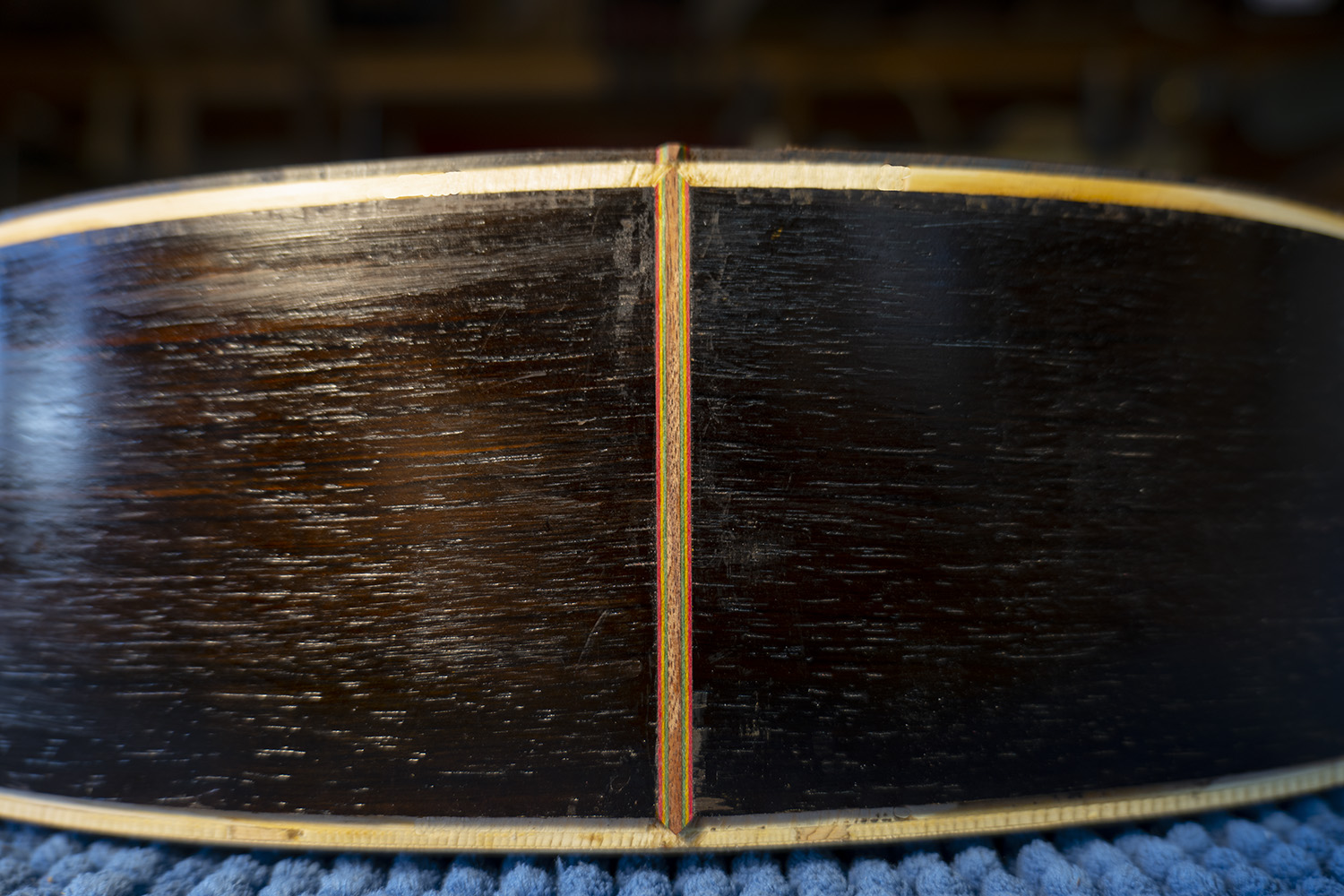

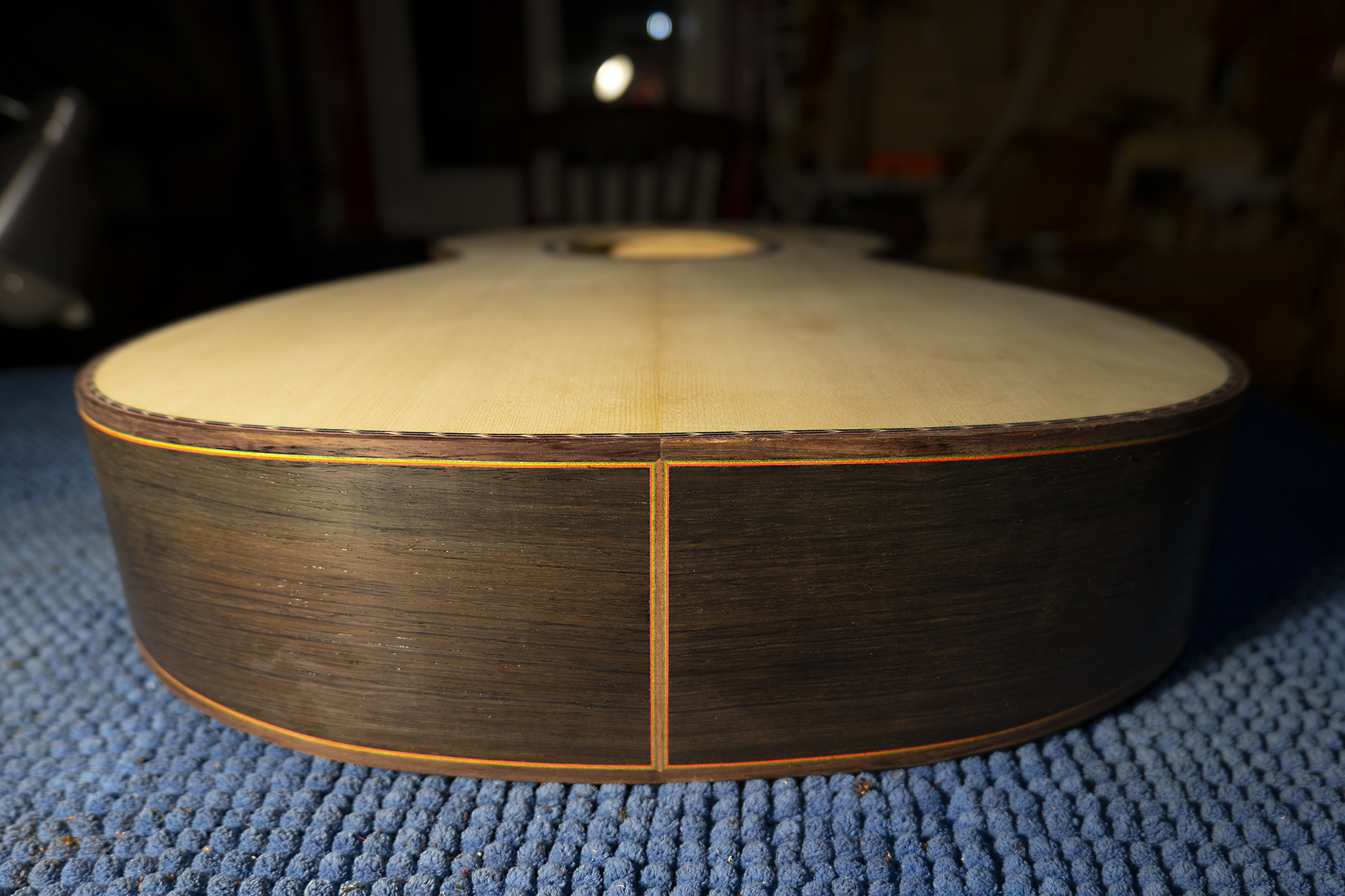

The back and sides wood I picked are dark traditional Brazilian rosewood. Clearly nicely figured, but it was only when I applied Shellac lacquer that I realised just how dramatic it was. With the shiny Shellac and under my bench lights it looks absolutely wonderful.

The shellac will be scraped and sanded off later, but there are good reasons for applying it now.

1. When removing tape that holds the binding, it can pull little lengths of wood from the grain; the shellac prevents this.

2. When scraping and sanding the finished instrument prior to going into the spray booth, the dark shellac shows the areas still needing more work.

3. The shellac helps fill grain before lacquering in the spray booth.

Me, Colin, and the mandolin photo: Janet Fellows

Me, Colin, and the mandolin photo: Janet Fellows