Anniversary MS model build part 3

Preparing lining and bending sides

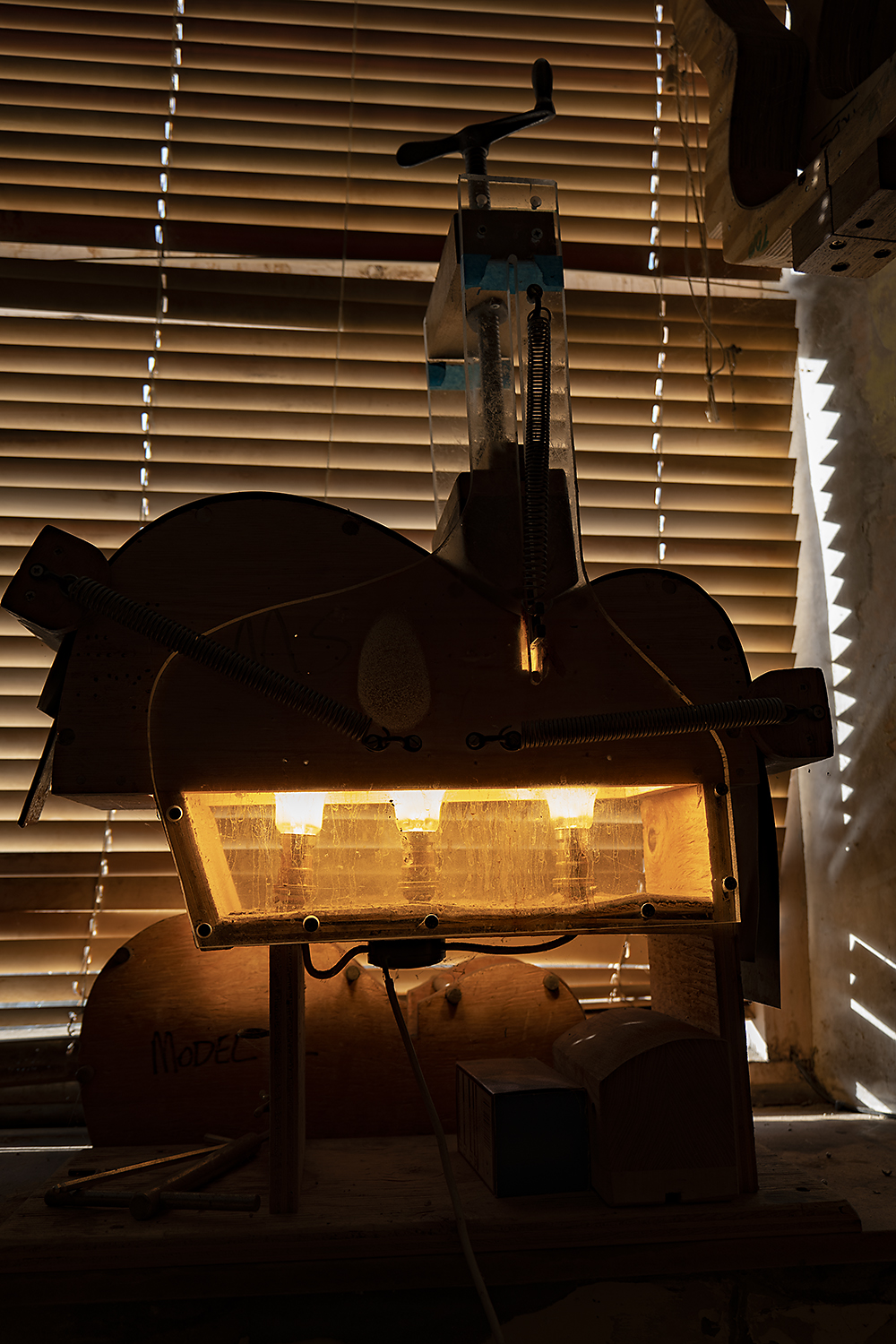

Shown right is my old Fox bender, still heated by filament light bulbs instead of the electric blankets more commonly used these days.

I don’t often use the Fox bender for sides these days, I get better results hand bending (on an electrically heated bending iron), then fitting them in the mould and putting this on the stove overnight, as shown below. But because the mould was in use, on this occasion I used the Fox for the linings (mine are solid spruce) though these were also finished on the stove.

When hand bending sides, I prefer to damp the wood first, but Brazilian rosewood varies so much this isn’t always sufficient. I had to soak these sides overnight before I could bend them on the heated hand bender.

Linings are so thick they require several days soaking before being bent to shape.

After hand bending, wetting the sides and leaving them in gentle overnight heat fixes the shape

After hand bending, wetting the sides and leaving them in gentle overnight heat fixes the shape

When I’m happy the sides are perfectly shaped, I trim neck and heel joins and glue them onto blocks (shown right); laminated spruce for the tail block, solid mahogany for the heel block. At the tail I leave a space for the centre inlay of black and colours to fit into after routing the binding grooves.

Now the sides are ready to be scribed to the curve of the back and have the back linings fitted.

The ancient Fox bender heated by bulbs

The ancient Fox bender heated by bulbs

Laminated spruce tail block fitted, mahogany heel block gluing

Laminated spruce tail block fitted, mahogany heel block gluing