Collaboration with Colin Keefe

For a dozen years now I have concentrated on building flat-top guitars, but I’m regularly being asked to build citterns and bouzoukis; several people telling me mine were the best available. Now Colin Keefe and partner Janet will be working with me to build my citterns and bouzoukis.

Colin became interested in building them after fitting a new back to one of my very early citterns, the one owned by Andy Irvine, taken to the US by Paul Brady, but returning with a split back. Colin did a wonderful job, building and fitting purfling in an exact match of my original: a perfect looking and perfectly constructed major repair. The owner was so pleased with it, he and Colin brought it to show me. Both Colin and the repair impressed me, and the idea of collaboration was born.

Colin has experience and training that few builders can match, and his work reflects this. His guitars are excellently put together and his renovations, for which he is becoming famous, are immaculate. His CV can be accessed here.

Colin proudly showing he can finger E major

Colin proudly showing he can finger E major

Colin marking out a fingerboard

Colin marking out a fingerboard

For the past several years Colin and Janet have been working from their workshop in Long Eaton, near Nottingham, but are now in process of moving to the North East, looking at premises a few miles from me, making regular contact easier.

Janet profiling frets

Janet profiling frets

Colin has already begun building instruments to my design. This isn’t easy at a distance, as my plans are comprehensible to me but not necessarily to anyone else. Even so, he has built a mandolin virtually indistinguishable from mine in both sound and appearance. Now he and Janet are moving so much closer, collaboration will be easier.

I’ll be giving more information as to cittern and bouzouki availability soon.

Jonny testing the recording setup

Jonny testing the recording setup Louis and Jonny setting up to record Douglas Fir New World

Louis and Jonny setting up to record Douglas Fir New World

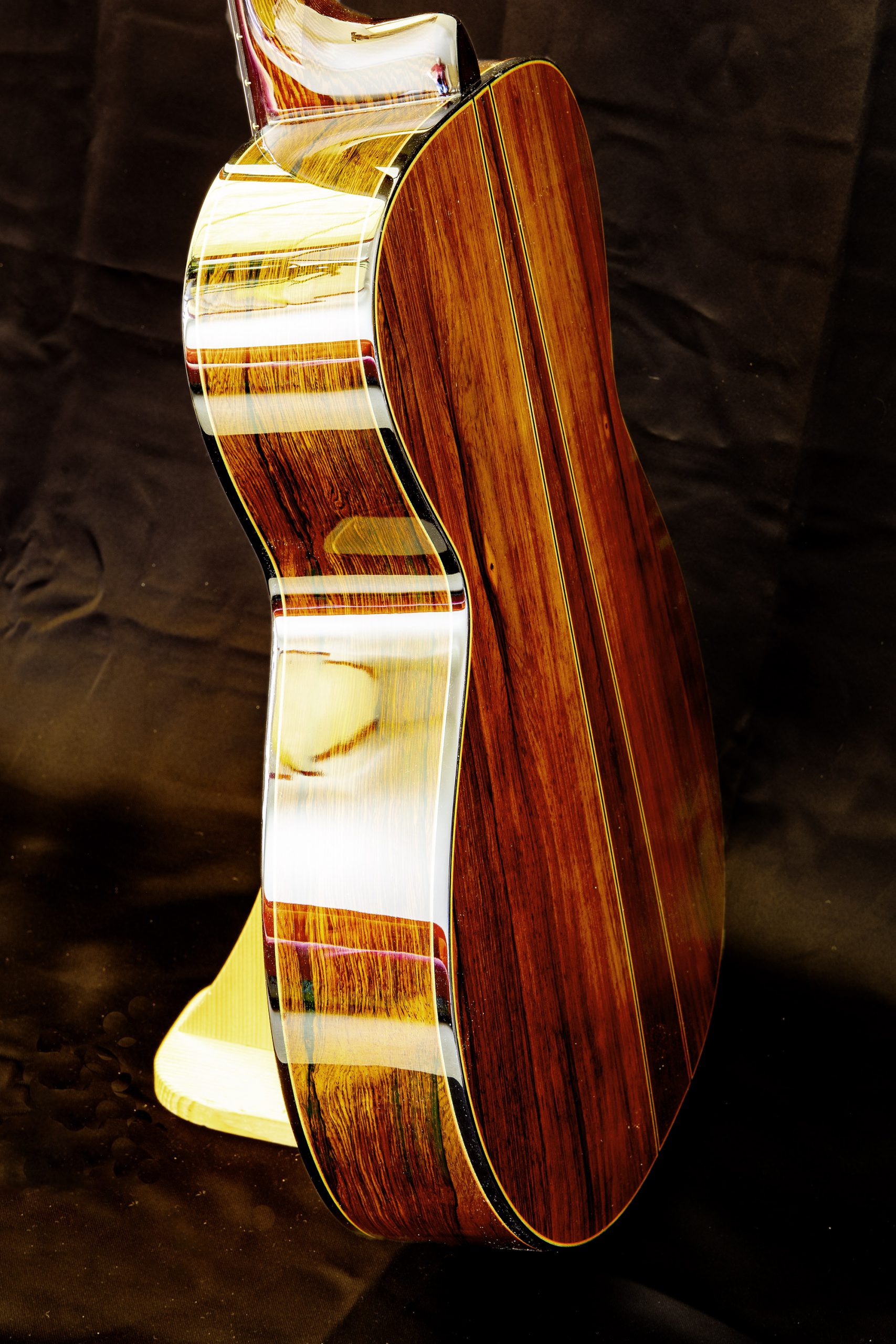

The old soundboard and dusty end of the fingerboard have been removed, leaving the top lining and the neck extension visible. The Wengé neck extension was reluctant to release the soundboard and suffered minor damage which will be sorted later. The body end of the truss rod is just visible.

The old soundboard and dusty end of the fingerboard have been removed, leaving the top lining and the neck extension visible. The Wengé neck extension was reluctant to release the soundboard and suffered minor damage which will be sorted later. The body end of the truss rod is just visible. The soundboard clamped on while the glue dries – I love these wooden cam clamps.

The soundboard clamped on while the glue dries – I love these wooden cam clamps. The soundboard trimmed to body size. The area above the neck extension had been removed before fitting.

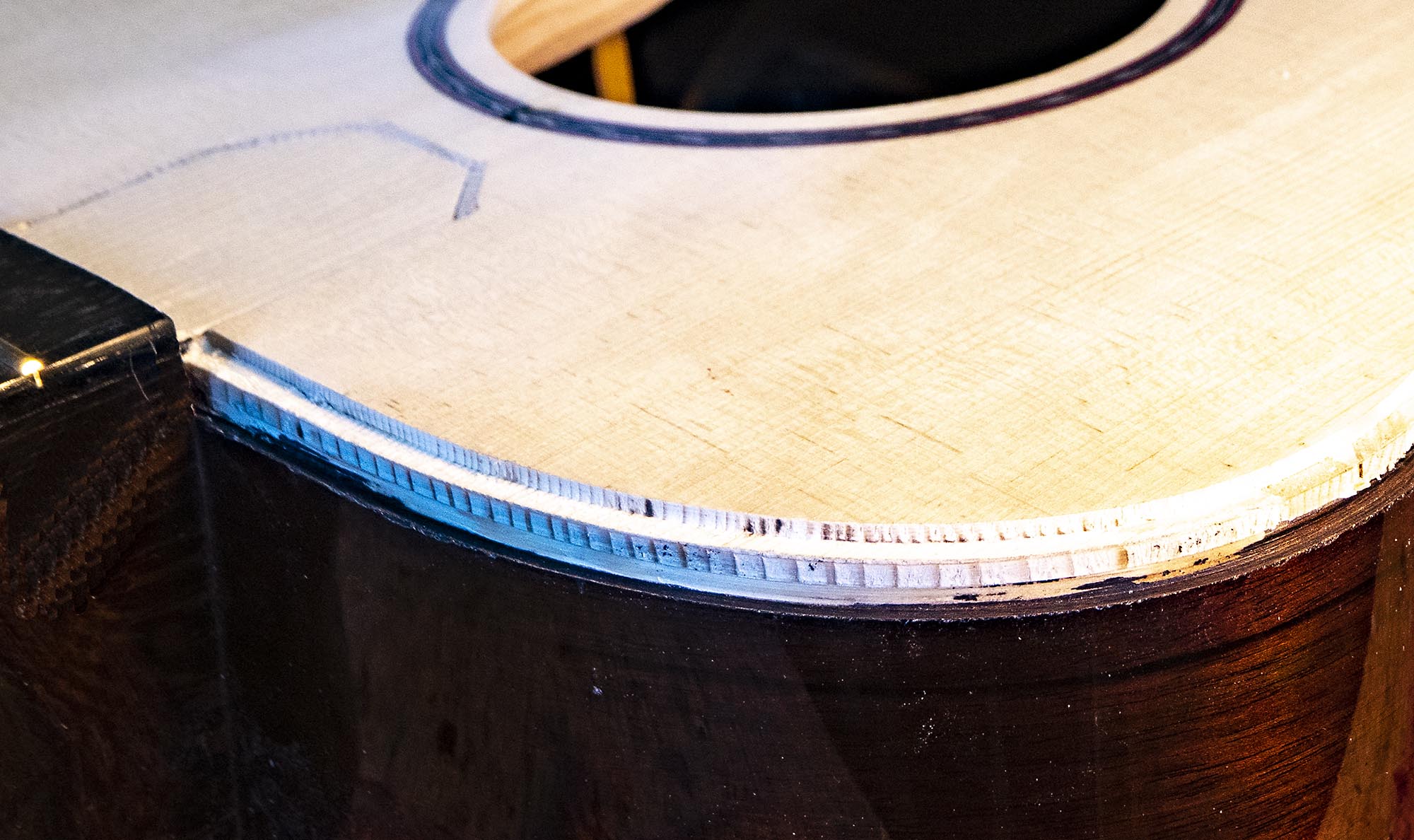

The soundboard trimmed to body size. The area above the neck extension had been removed before fitting. The neck extension has been locked firmly against the soundboard, and the space above it filled with another piece of spruce. It sits proud but will be leveled when the glue is dry; the neck and body are now rigidly connected and everything is ready for binding.

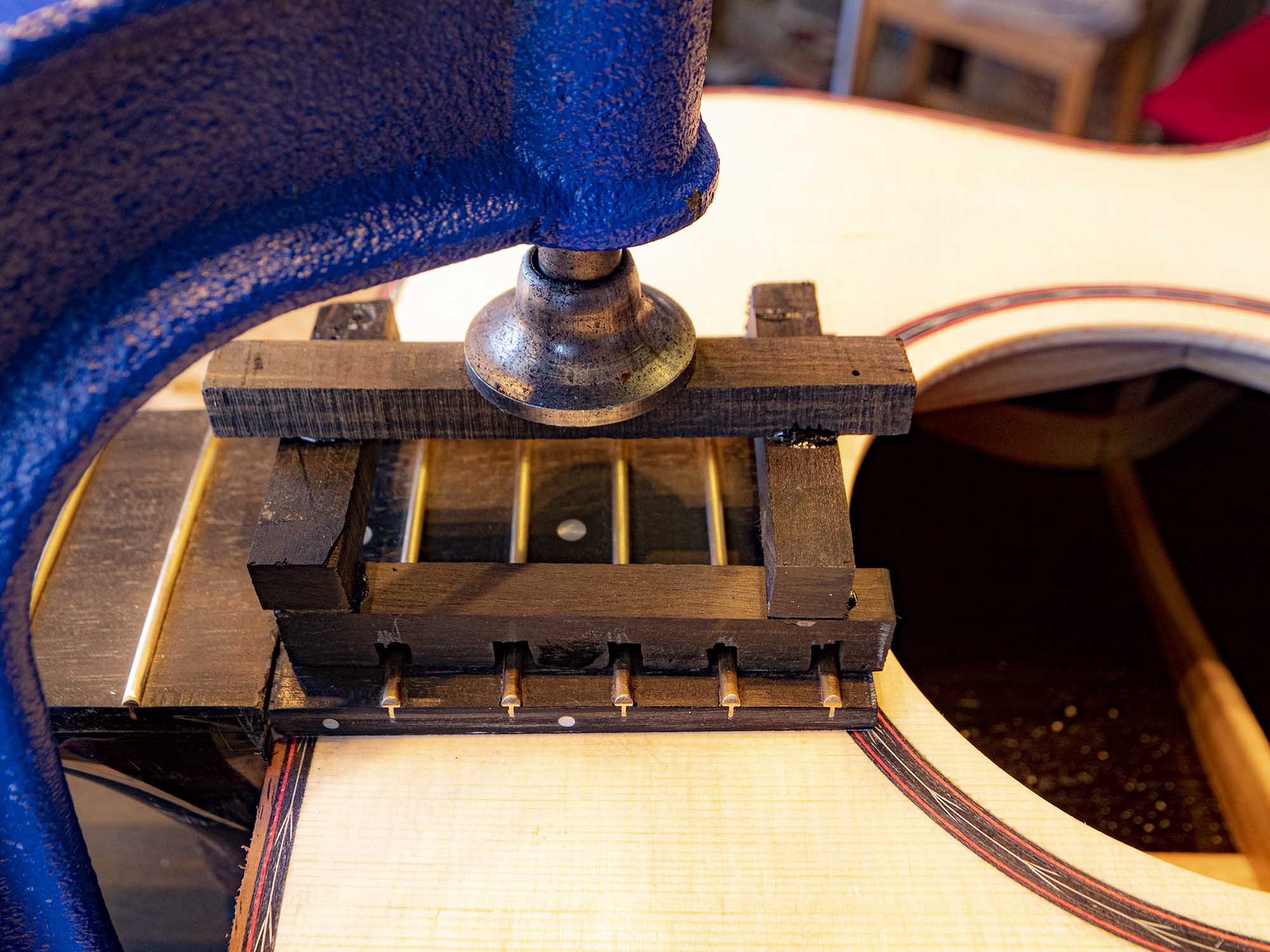

The neck extension has been locked firmly against the soundboard, and the space above it filled with another piece of spruce. It sits proud but will be leveled when the glue is dry; the neck and body are now rigidly connected and everything is ready for binding. I rout the binding and trim ledges with the ledge routing jig; the neck made life difficult and didn’t allow the jig to rout right up to it. So the last inch or so both sides I cut by hand. The neck also complicated fitting the neck end of the binding, which has to be fed between the soundboard and end of the neck.

I rout the binding and trim ledges with the ledge routing jig; the neck made life difficult and didn’t allow the jig to rout right up to it. So the last inch or so both sides I cut by hand. The neck also complicated fitting the neck end of the binding, which has to be fed between the soundboard and end of the neck. The ledges complete, the binding and two piece trim have been bent to shape on the bender. I’ve mitred the tail end of the bindings to join up with the back trim, and all have been cut to exact length. I was now ready to bind.

The ledges complete, the binding and two piece trim have been bent to shape on the bender. I’ve mitred the tail end of the bindings to join up with the back trim, and all have been cut to exact length. I was now ready to bind. The bindings and trim are glued and firmly bound with garish tape. This could be the colour James Joyce described as ‘a scrotum tightening shade of green’.

The bindings and trim are glued and firmly bound with garish tape. This could be the colour James Joyce described as ‘a scrotum tightening shade of green’.

Ebony bridge blank

Ebony bridge blank Bridge shaped and matched to soundboard curve, holes and saddle slots cut

Bridge shaped and matched to soundboard curve, holes and saddle slots cut Looking perfect, now ready for Dave and the spraybooth. The taped off bridge area can just be seen, the tape will be removed after lacquering so the bridge glues onto bare wood.

Looking perfect, now ready for Dave and the spraybooth. The taped off bridge area can just be seen, the tape will be removed after lacquering so the bridge glues onto bare wood.

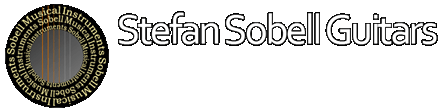

Much loved 2020 African Blackwood and German spruce 2D with Santos rosewood binding

Much loved 2020 African Blackwood and German spruce 2D with Santos rosewood binding