MS Anniversary model part 7

Making the Bridge

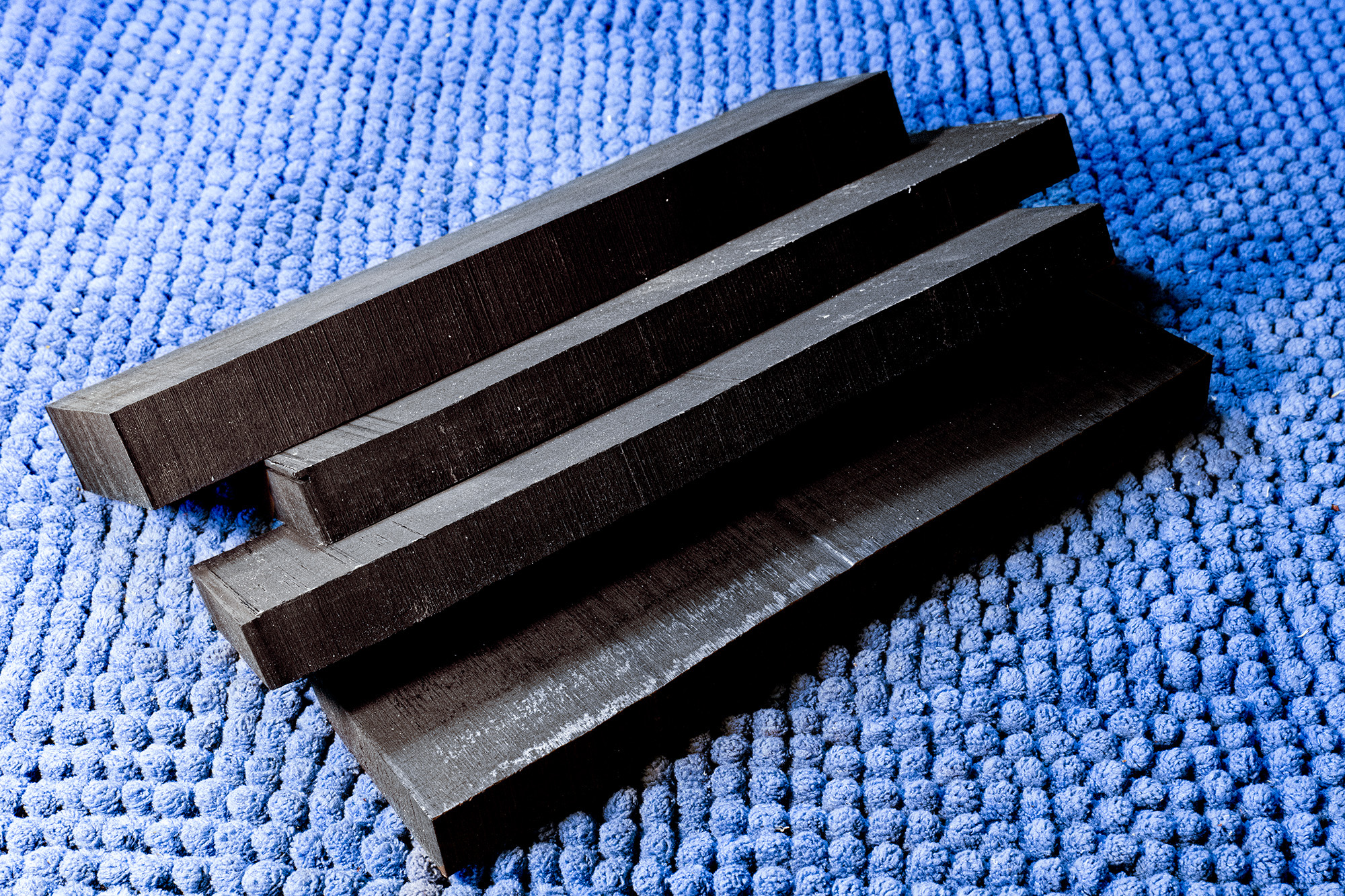

My bridge is always ebony. I am currently using ebony from a board I bought from Craft Supplies in Derbyshire. Goodness knows how long ago Craft Supplies ceased trading, but however long that is, I’ve had this ebony longer. It is beautiful; straight grained, very black (although I personally don’t mind some lighter figure), and even and creamy to work.

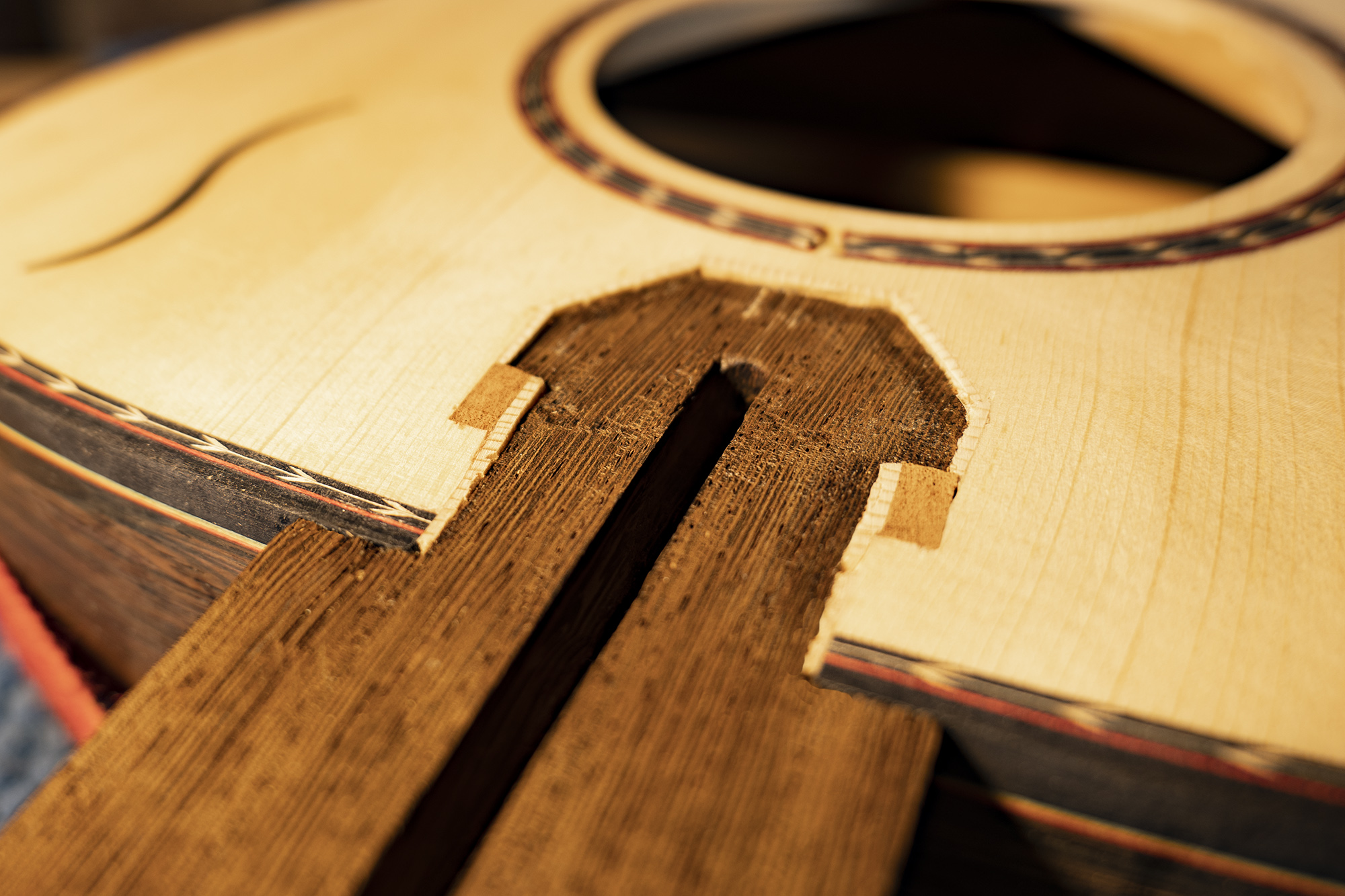

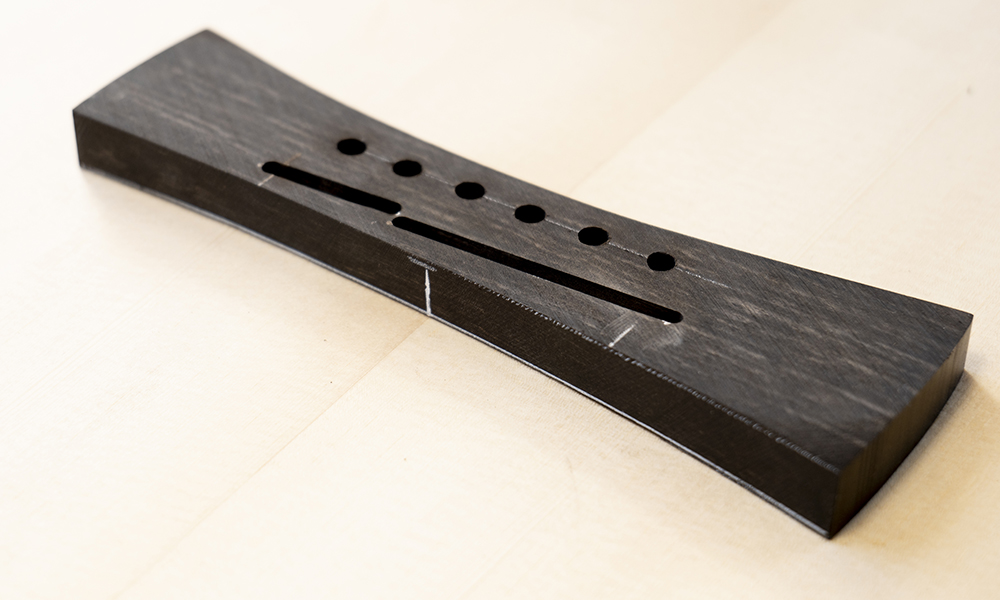

Because the bridge is to be fitted to a curved soundboard, it must be curved to fit. As the soundboard curve can vary slightly from guitar to guitar, the bottom of the bridge has been shaped to fit this MS soundboard.

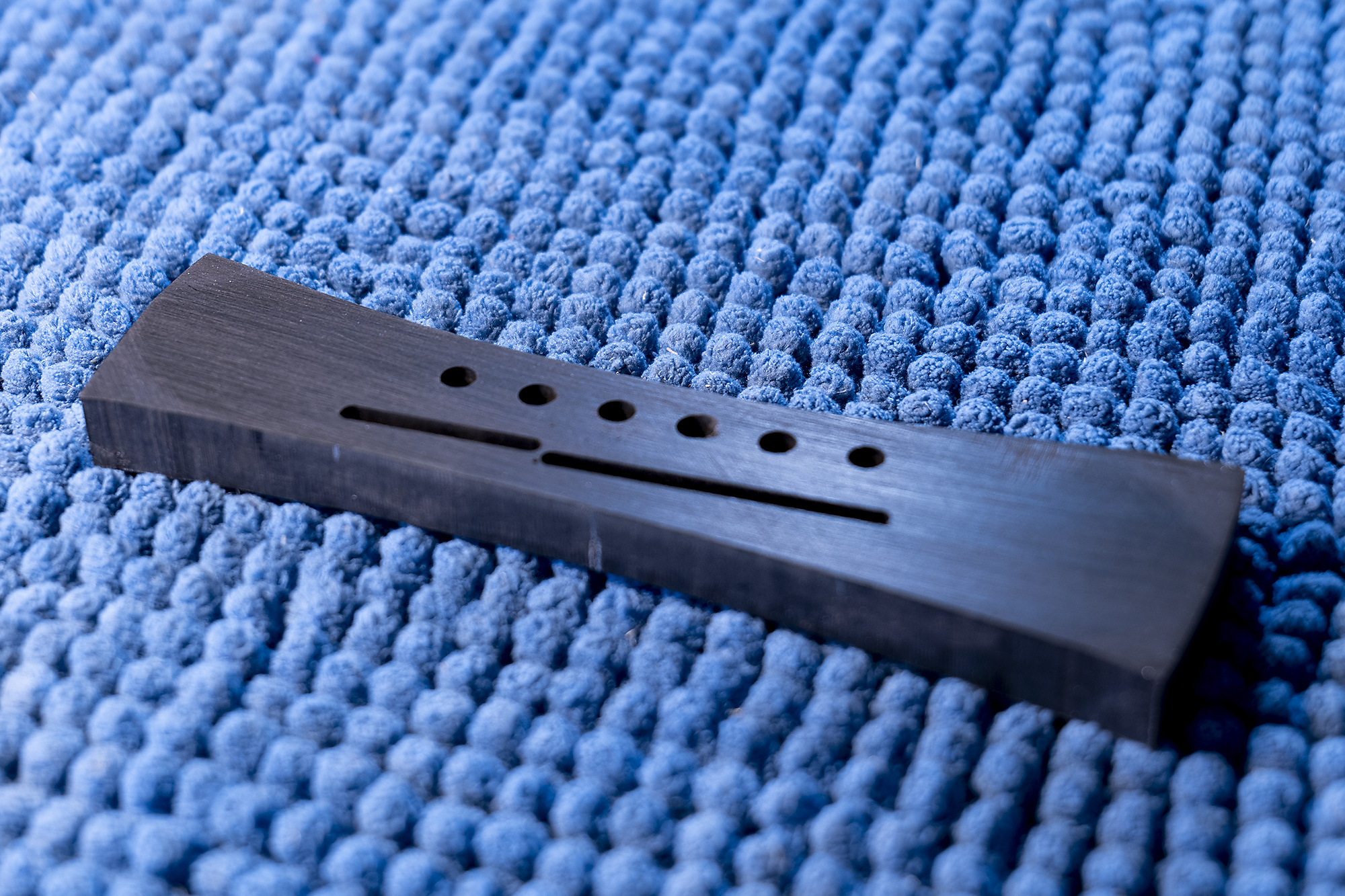

Only the outer two holes go right through the bridge; these are used to locate the bridge when gluing. The middle four are blind so that they don’t fill with glue during gluing.

Bridge blanks cut from the Craft Supplies board

Bridge blanks cut from the Craft Supplies board

Holes drilled and saddle slots routed

Holes drilled and saddle slots routed

Bridge shaped on the sander, ready for final hand trimming and sanding

Bridge shaped on the sander, ready for final hand trimming and sanding

Bridge finished. Hole countersinking and final fine sanding will take place when the bridge is glued in place

Bridge finished. Hole countersinking and final fine sanding will take place when the bridge is glued in place

Heel block stamped 57th MS model, serial no 521, Anniversary Model 8

Heel block stamped 57th MS model, serial no 521, Anniversary Model 8 Neck, body and wedges ready for assembly

Neck, body and wedges ready for assembly Neck in place, mahogany wedges driven in and neck locked against the soundboard with little spruce wedges

Neck in place, mahogany wedges driven in and neck locked against the soundboard with little spruce wedges The last process: gluing on the ebony heel cap. Now it stands overnight before I begin fitting the fingerboard

The last process: gluing on the ebony heel cap. Now it stands overnight before I begin fitting the fingerboard Fingerboard fitted and (some time later) Wengé neck shaped. Wengé is tricky to work. The grain runs both ways, when planing or chiseling, there is always grain against you so the blade wants to dig in. It’s abrasive, so quickly blunts tools used on it, and the dust is not good. If you get a splinter it should be taken out soon; left in, the flesh around it will fester.

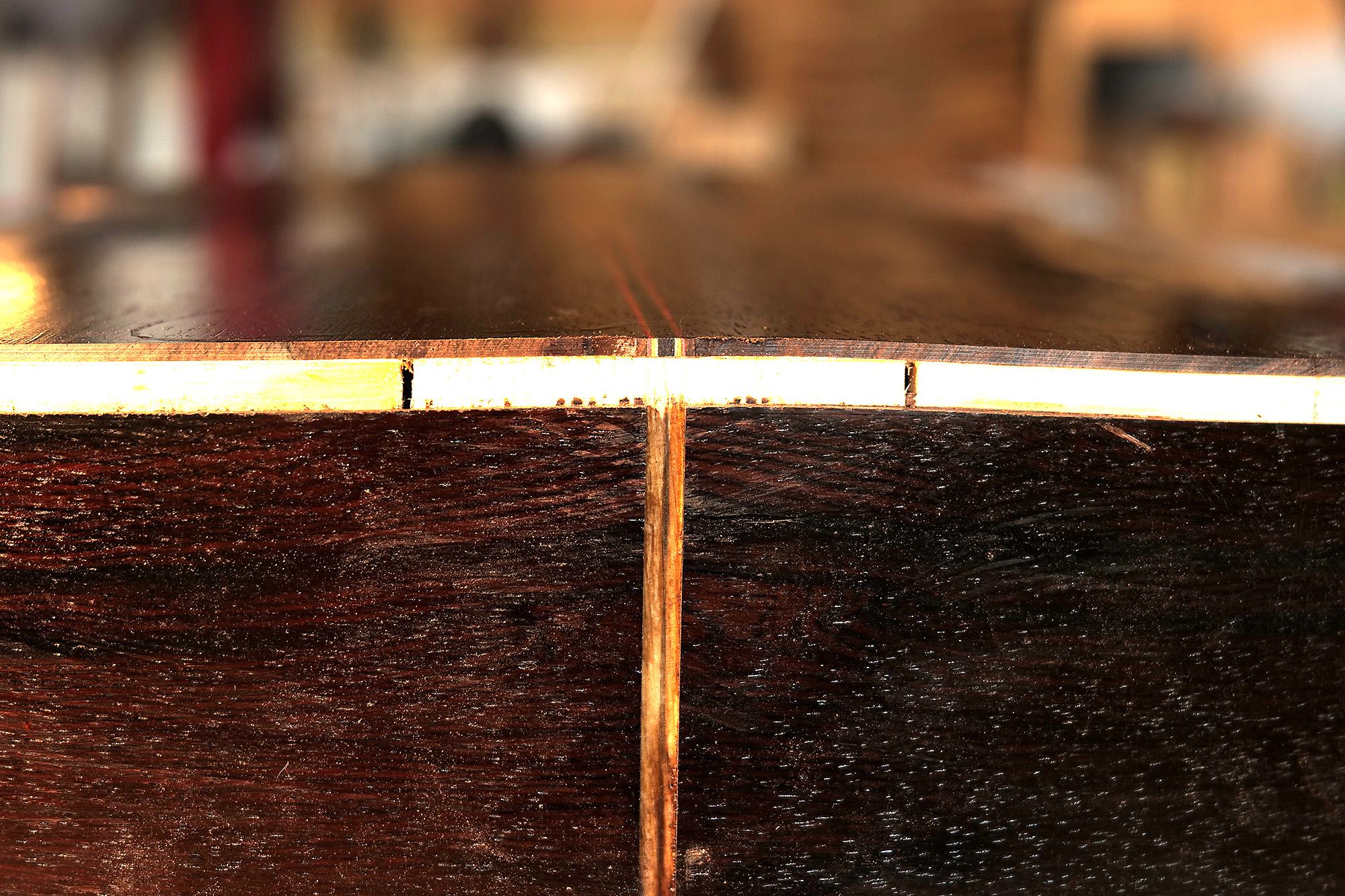

Fingerboard fitted and (some time later) Wengé neck shaped. Wengé is tricky to work. The grain runs both ways, when planing or chiseling, there is always grain against you so the blade wants to dig in. It’s abrasive, so quickly blunts tools used on it, and the dust is not good. If you get a splinter it should be taken out soon; left in, the flesh around it will fester. Top stepped ledge for binding and arrowhead trim plus red pinstripe

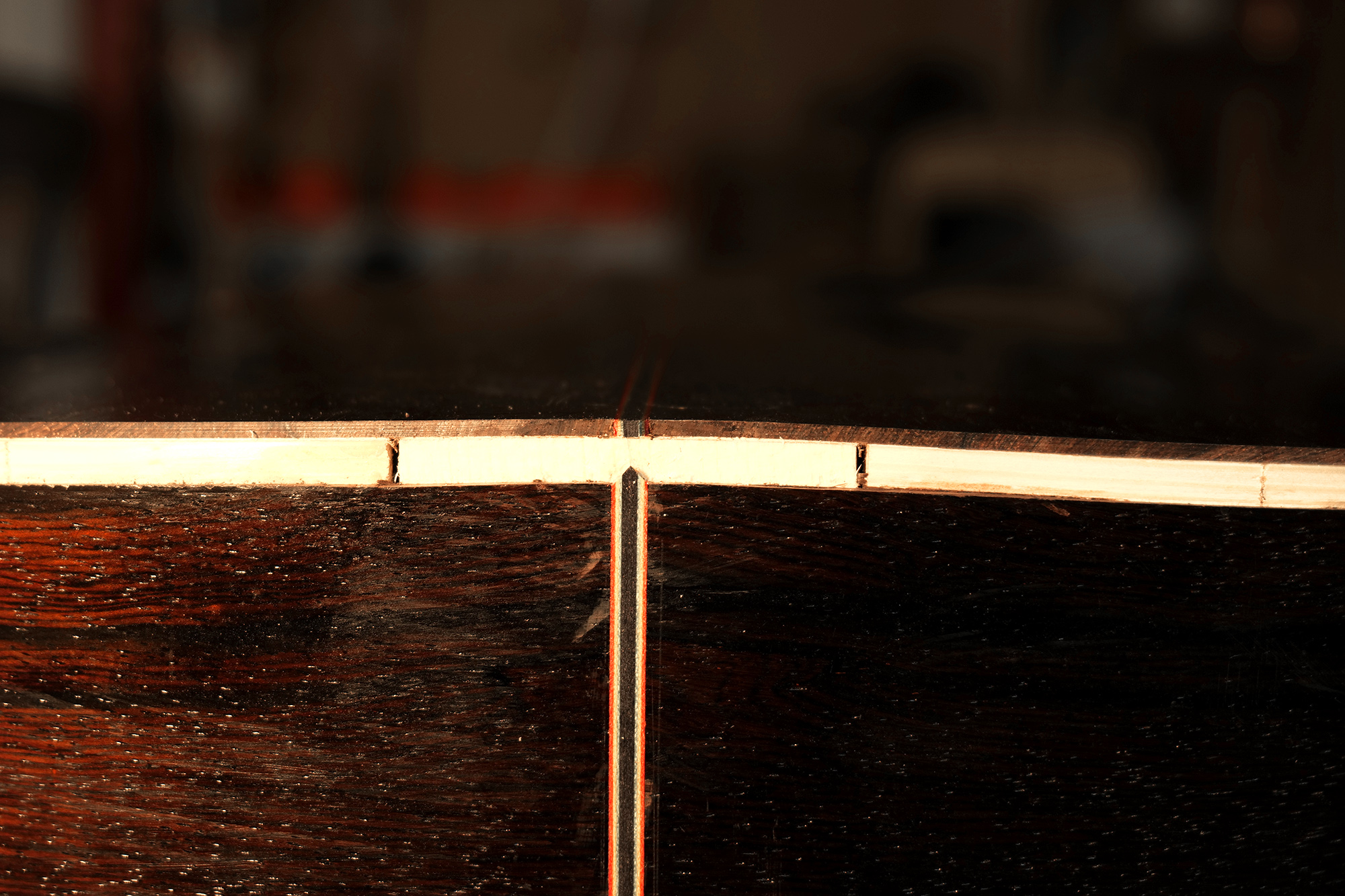

Top stepped ledge for binding and arrowhead trim plus red pinstripe Bottom stepped ledge for binding and three colour trim

Bottom stepped ledge for binding and three colour trim Sacrificial wood in place

Sacrificial wood in place Sacrificial wood removed

Sacrificial wood removed Final trim in place and mitred

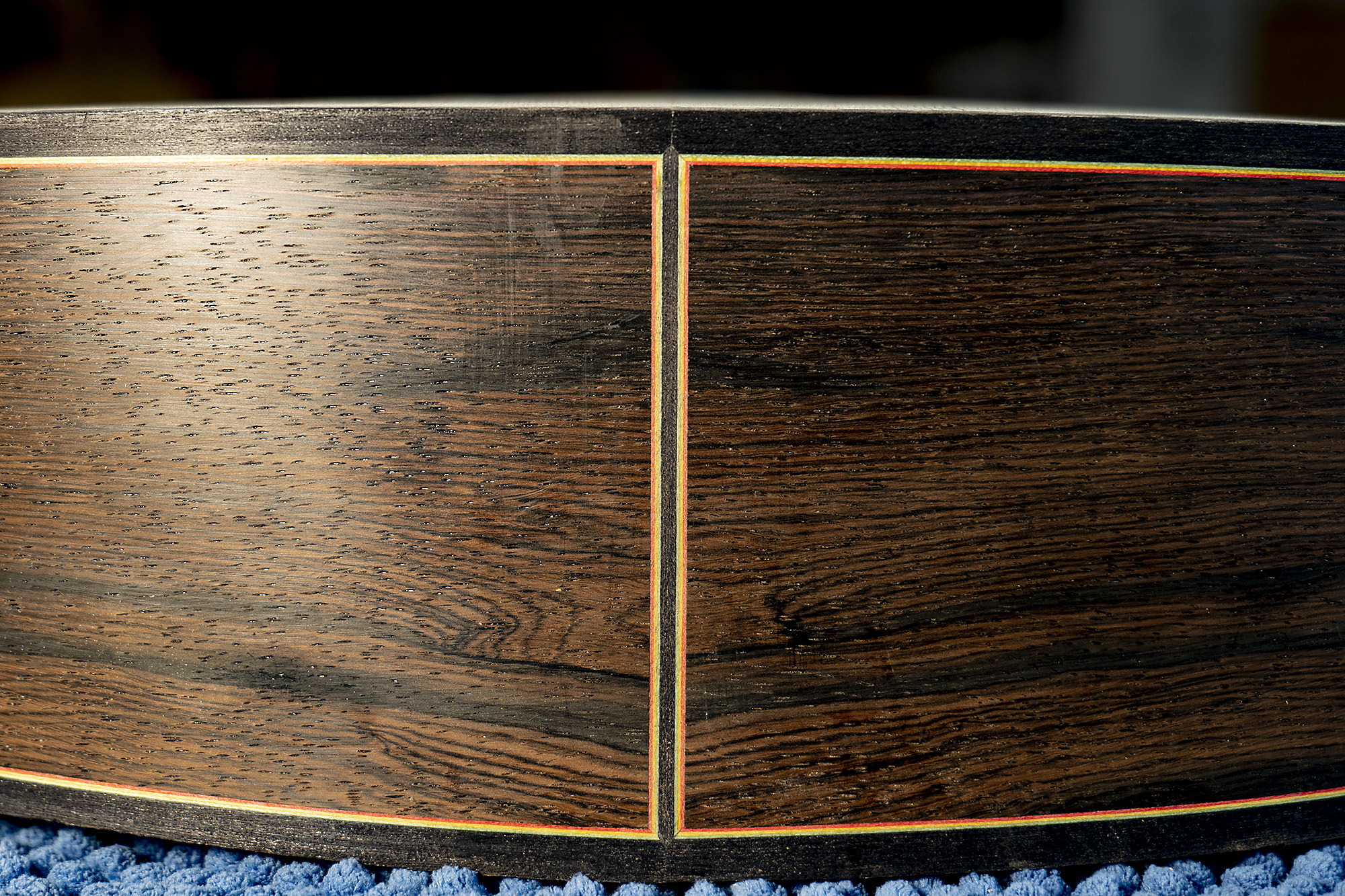

Final trim in place and mitred Tail trim mitred into the binding

Tail trim mitred into the binding

Back and soundboard finished

Back and soundboard finished Lining clamped with strong spring clamps

Lining clamped with strong spring clamps Soundboard clamped to sides with cam clamps

Soundboard clamped to sides with cam clamps Back and sides with coat of shellac lacquer

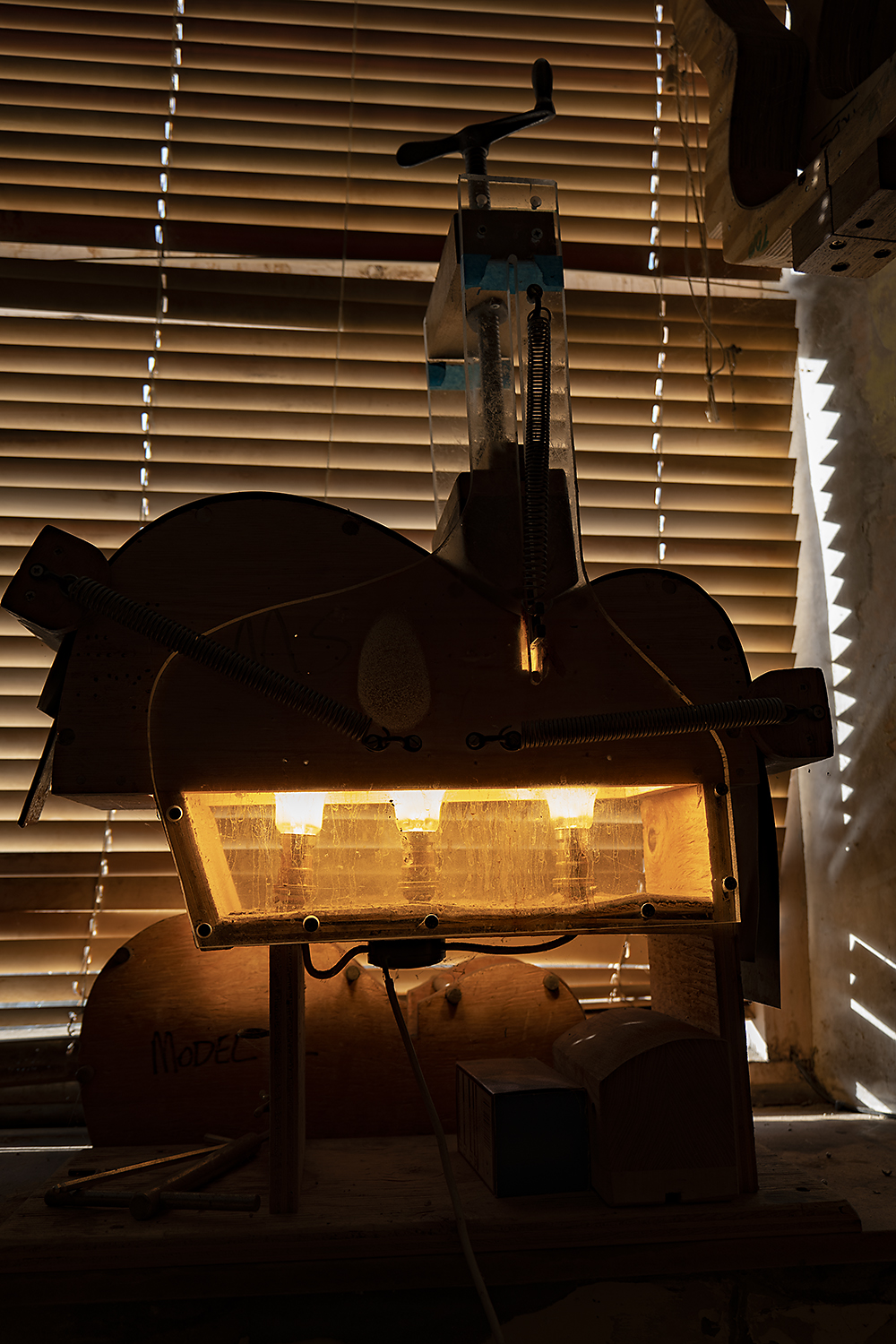

Back and sides with coat of shellac lacquer After hand bending, wetting the sides and leaving them in gentle overnight heat fixes the shape

After hand bending, wetting the sides and leaving them in gentle overnight heat fixes the shape The ancient Fox bender heated by bulbs

The ancient Fox bender heated by bulbs Laminated spruce tail block fitted, mahogany heel block gluing

Laminated spruce tail block fitted, mahogany heel block gluing

2. Braces gluing in go-bar jig

2. Braces gluing in go-bar jig

3. Back and braces out of go-bar jig being trimmed and sanded

3. Back and braces out of go-bar jig being trimmed and sanded

Bridge shaped to soundboard curve, drilled and slotted

Bridge shaped to soundboard curve, drilled and slotted Bridge in its final shape. Writing identifies it as individually made to fit this guitar

Bridge in its final shape. Writing identifies it as individually made to fit this guitar