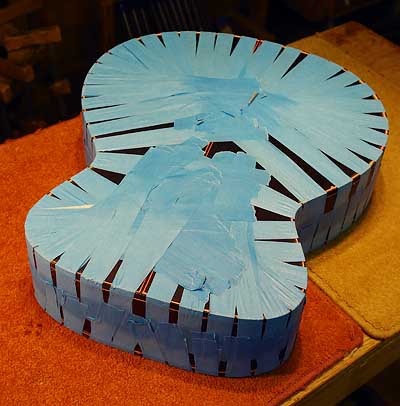

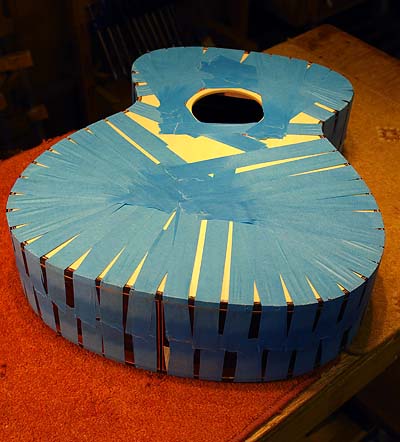

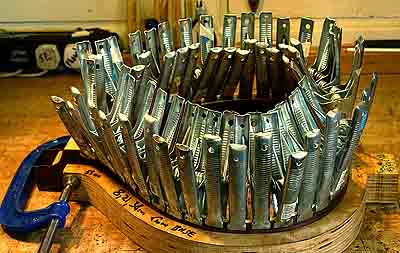

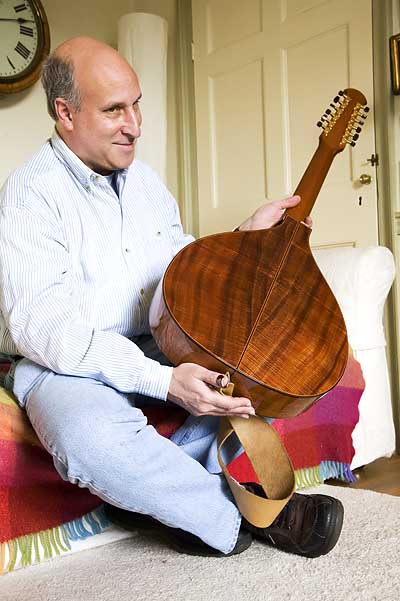

12 String large bodied cittern

Today Joseph Sobol collected his 12 string large bodied cittern. With polite persistence he eventually pursuaded me to build it from Koa and Port Orford cedar, woods I haven’t used before. The lower four pairs are octave strung.

This combination of woods turned out to be an inspired choice. Although I could play nothing on so many strings, Joseph makes it sound wonderful, like a church organ. He’s a great player (and not just on cittern – he also plays his own beautiful Bach arrangements on steel string guitar).

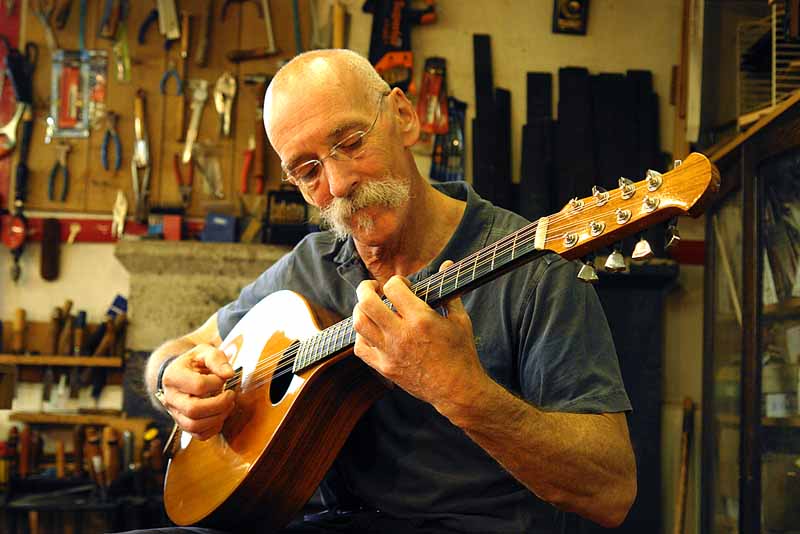

Here am I with the cittern, photographed by Joseph. I’m not even trying to play it because all those strings look as confusing to me as a railway goods yard.

And if I’m looking puzzled, it’s because I’m wondering, how a man who can play instruments like he does can have such trouble pressing the shutter button on a camera?

For those curious as to how so many photographs could be taken in so short a time, I should point out that the wall clock had stopped. Either that or we took one photograph every twelve hours.