.

The build is now complete. Next the guitar goes to Dave Wilson and the spraybooth; this will not be until be some time in the new year, so it will be a couple of months or more before I get it back.

When it comes back, I glue on the bridge, check, level and profile the frets, make and fit the bone nut and saddles, fit gold Gotoh 510 tuners (the best) and finally fit the strings.

Even then it isn’t finished. I adjust the nut grooves, fit the strings and bring them up to tension, check the neck relief and set the string action.

Then I like to let it stand a few weeks while the guitar settles in and I can check the string action again. By now it will have started to open up, though it will be months or even years before it reaches its peak and we can hear how it really sounds.

The impatient young man who started building nearly fifty years ago has had to learn patience.

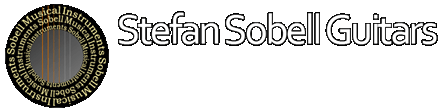

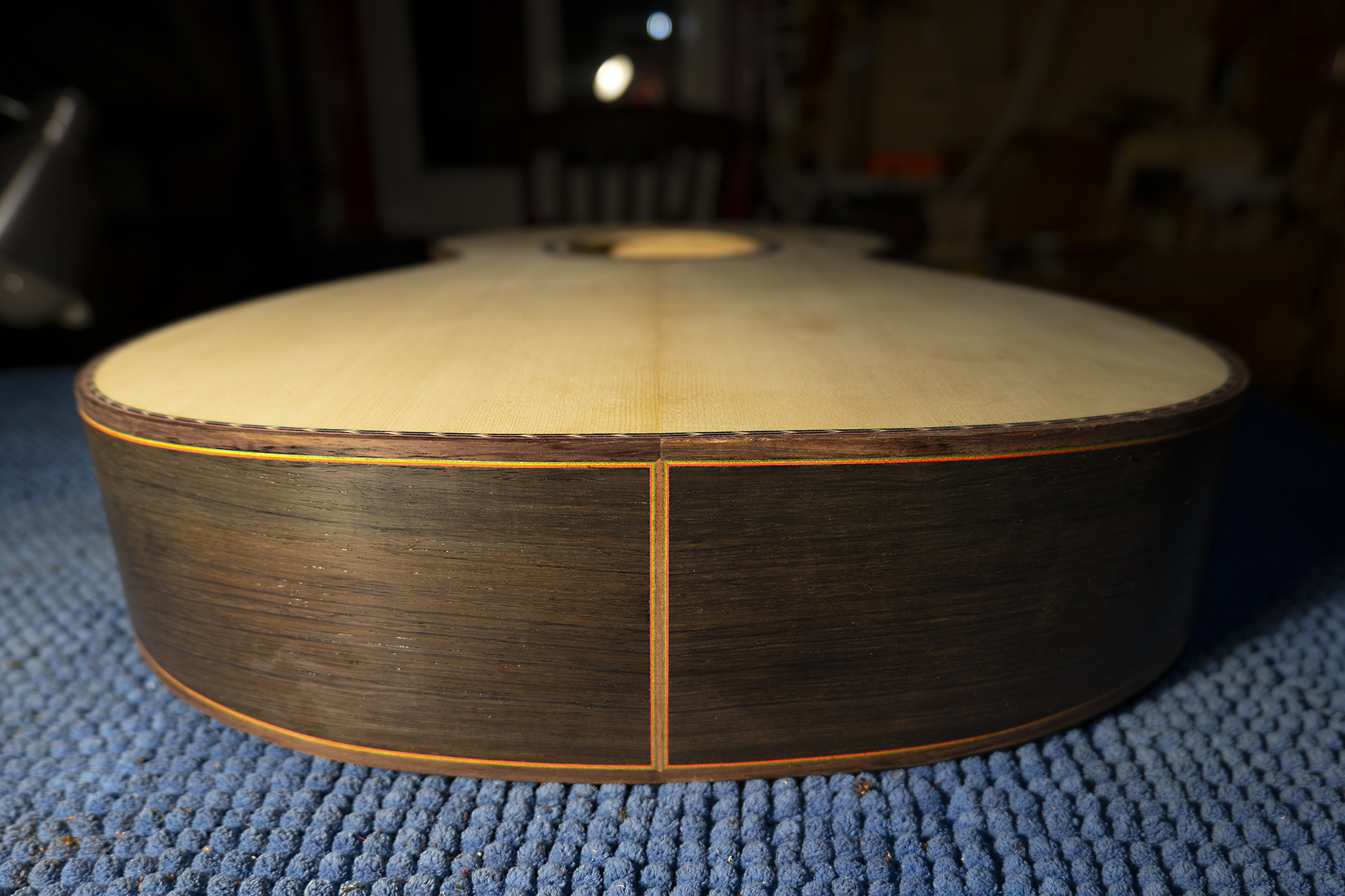

Old Brazilian rosewood, aged German spruce and aged ebony are lovely to work with. It sounds like a cliché, but it really is a privilege to work with such special woods.

Me, Colin, and the mandolin photo: Janet Fellows

Me, Colin, and the mandolin photo: Janet Fellows

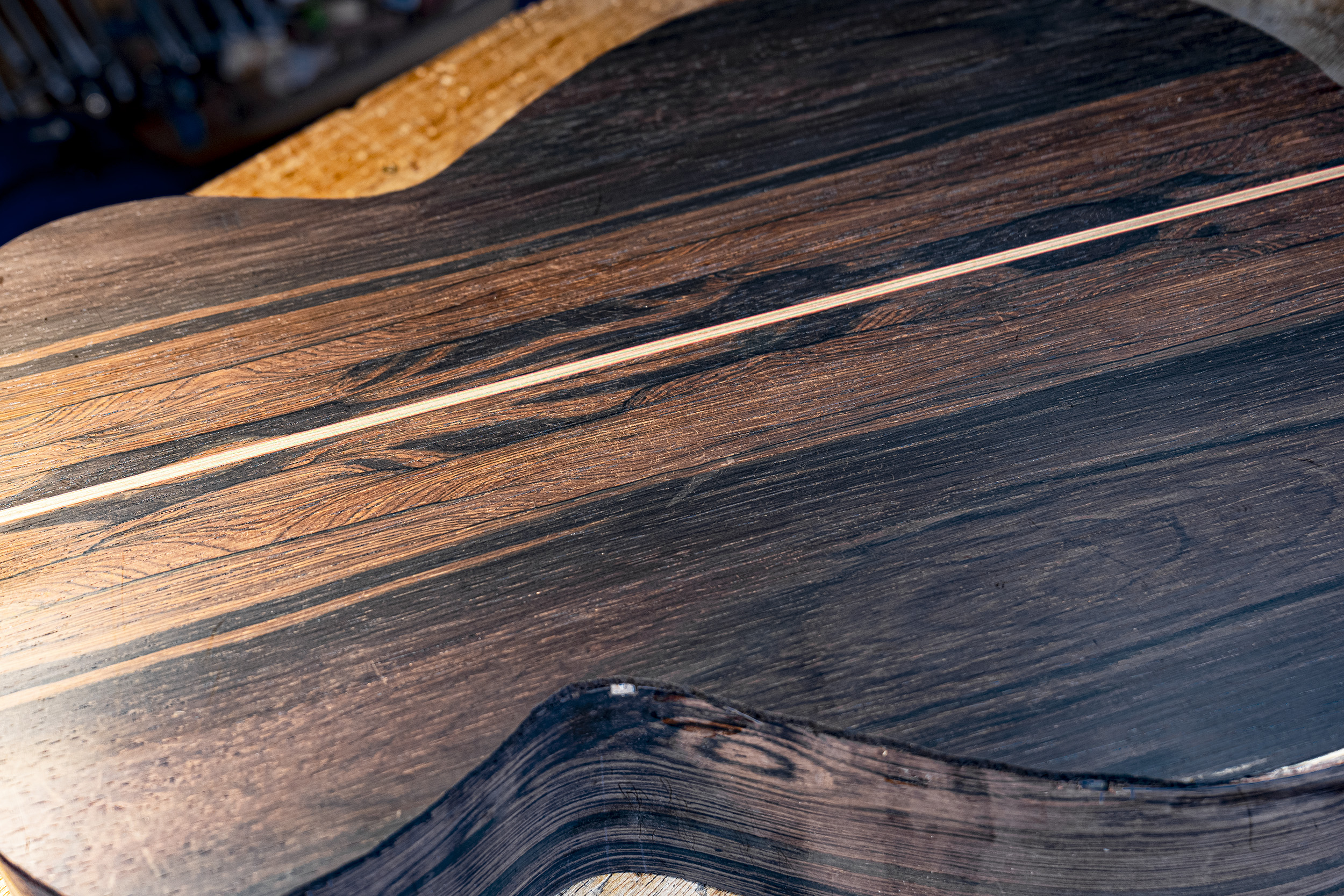

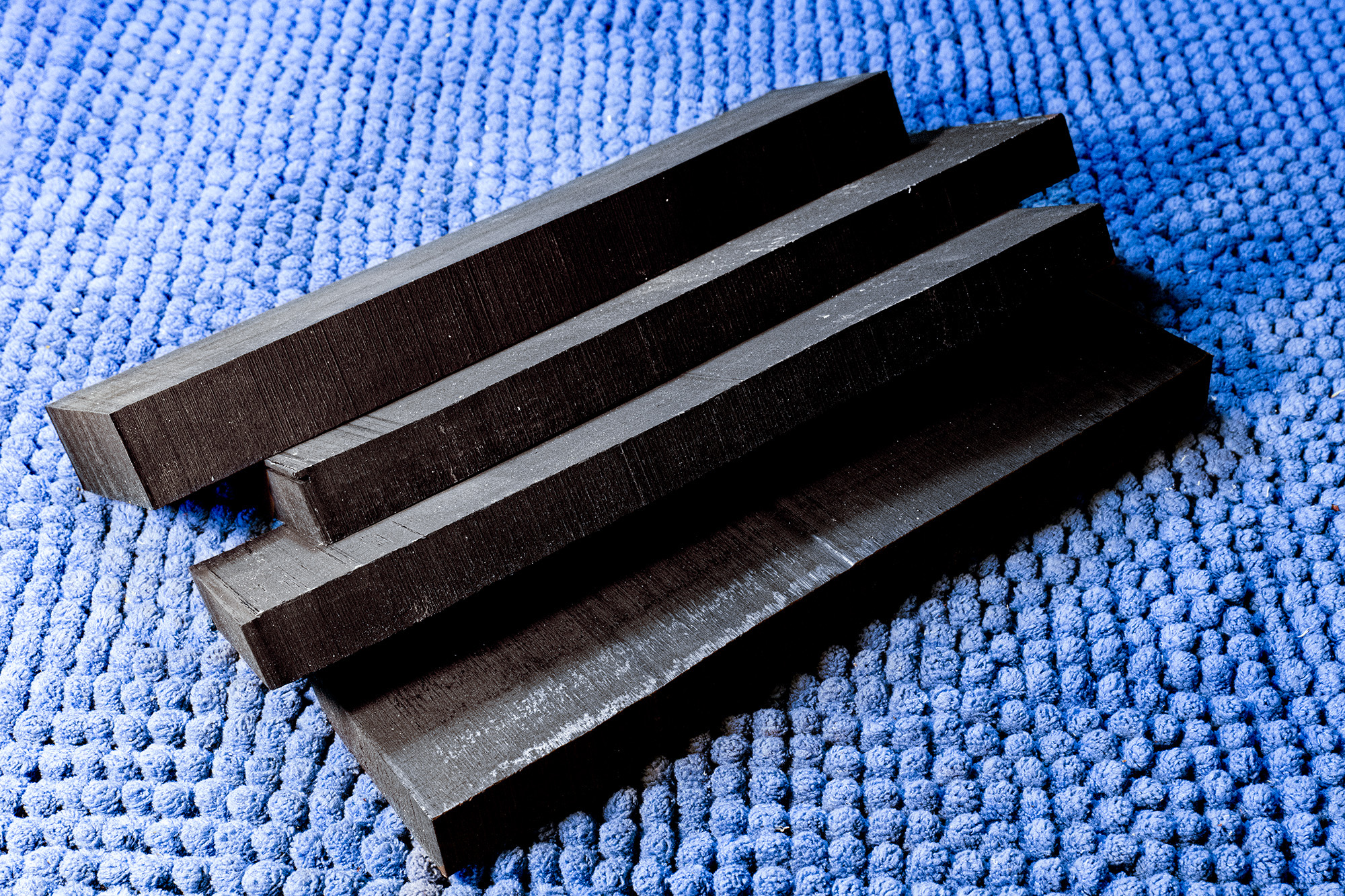

Bridge blanks cut from the Craft Supplies board

Bridge blanks cut from the Craft Supplies board

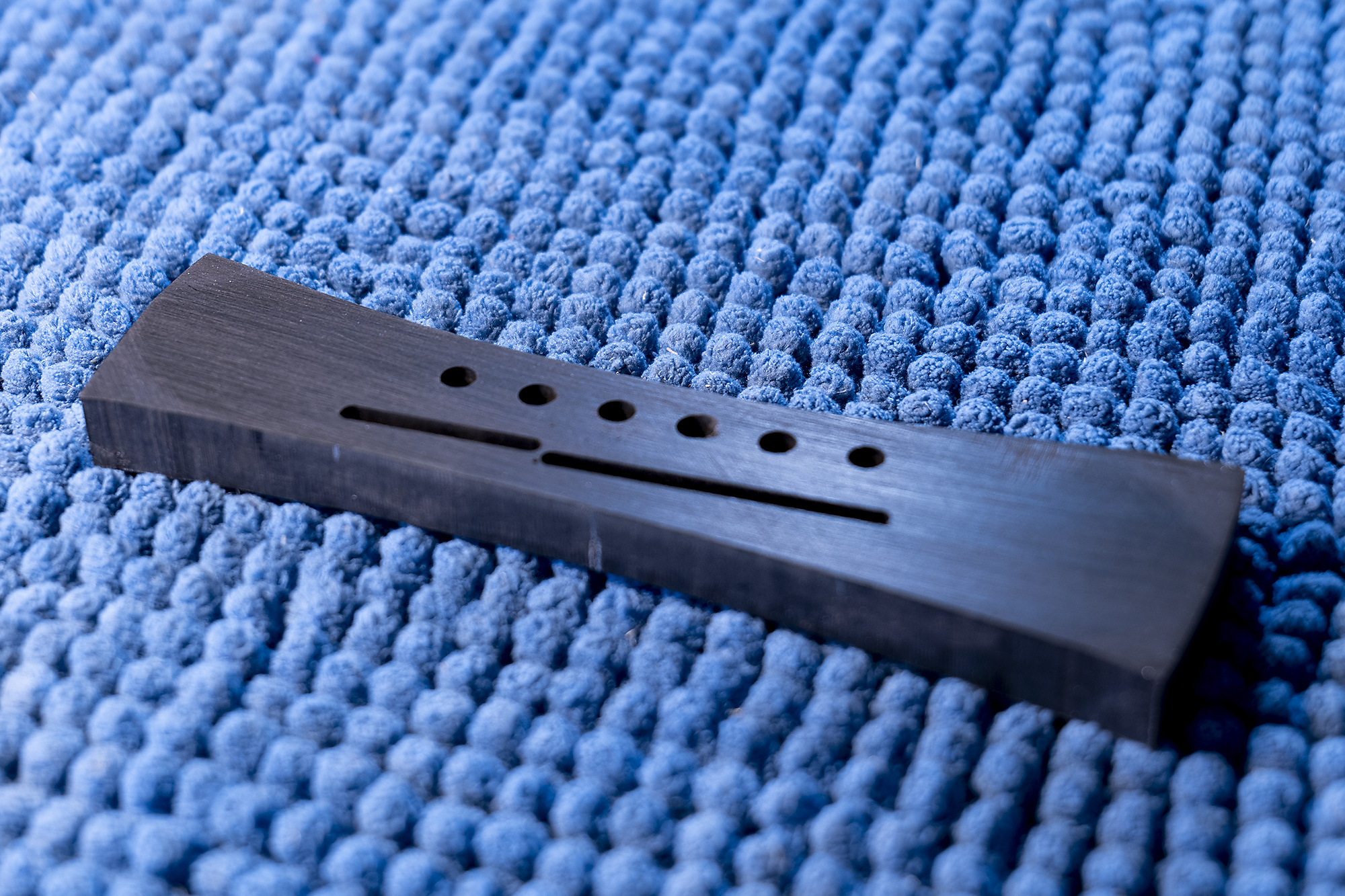

Holes drilled and saddle slots routed

Holes drilled and saddle slots routed Bridge shaped on the sander, ready for final hand trimming and sanding

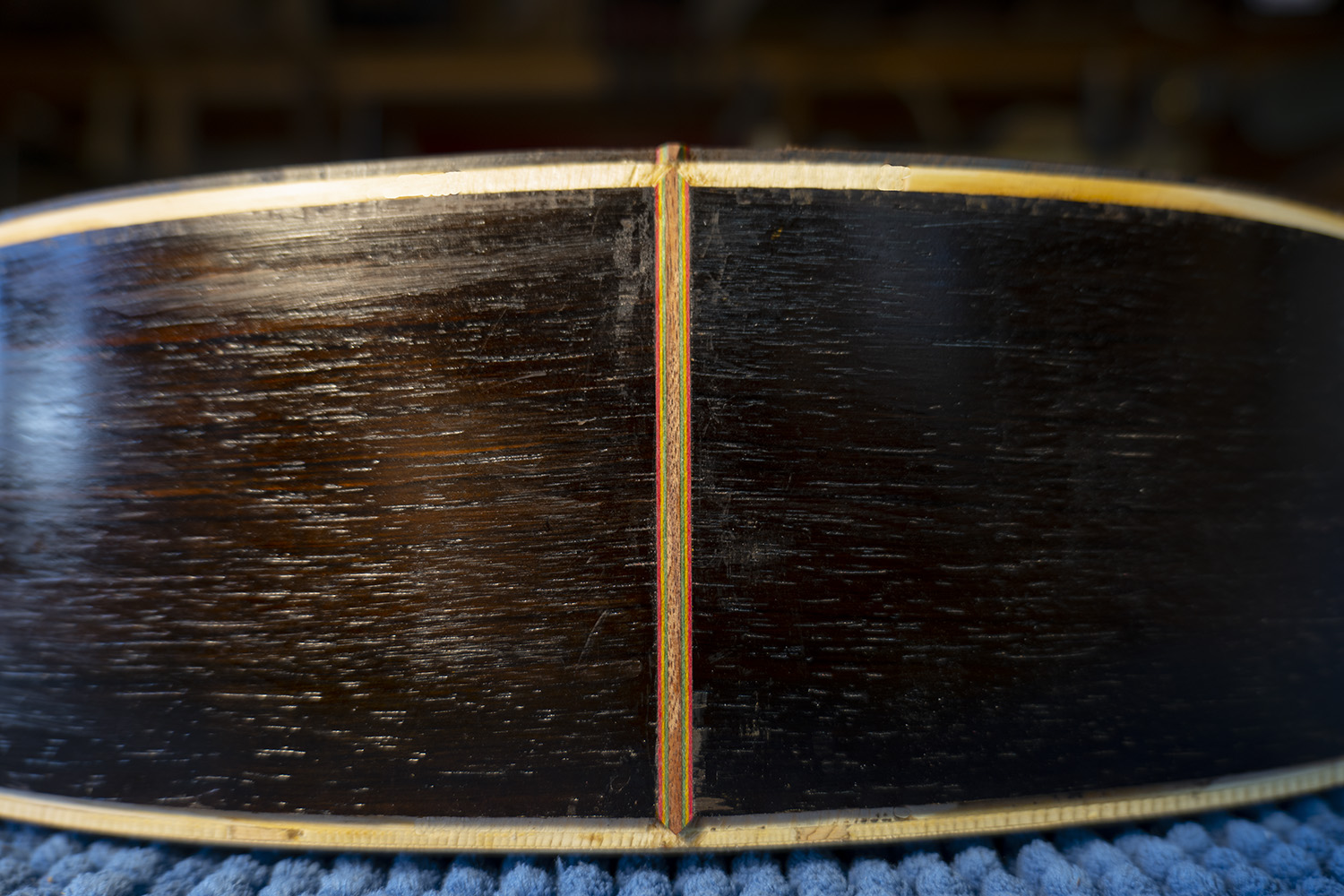

Bridge shaped on the sander, ready for final hand trimming and sanding Bridge finished. Hole countersinking and final fine sanding will take place when the bridge is glued in place

Bridge finished. Hole countersinking and final fine sanding will take place when the bridge is glued in place