And not just difficult, dangerous for many. Many will be in despair as to how they will manage financially, old and medically vulnerable people are aware that catching this virus could be serious and possibly fatal, and the problems society faces will drastically affect everyone. It’s a time for pulling together, and doing everything we can to help those around us, in particular those less fortunate than ourselves.

Liz and I are self-isolating, our kind younger neighbour will collect shopping for us.

Because I work alone, I am privileged in that I can continue working. Building guitars has been described, not without some justification, as my occupational therapy. But I’m not accepting visitors until further notice, for obvious reasons. However, shipping and courier companies tell me they are continuing to make deliveries, so I will be able to ship instruments out as usual.

In my workshop

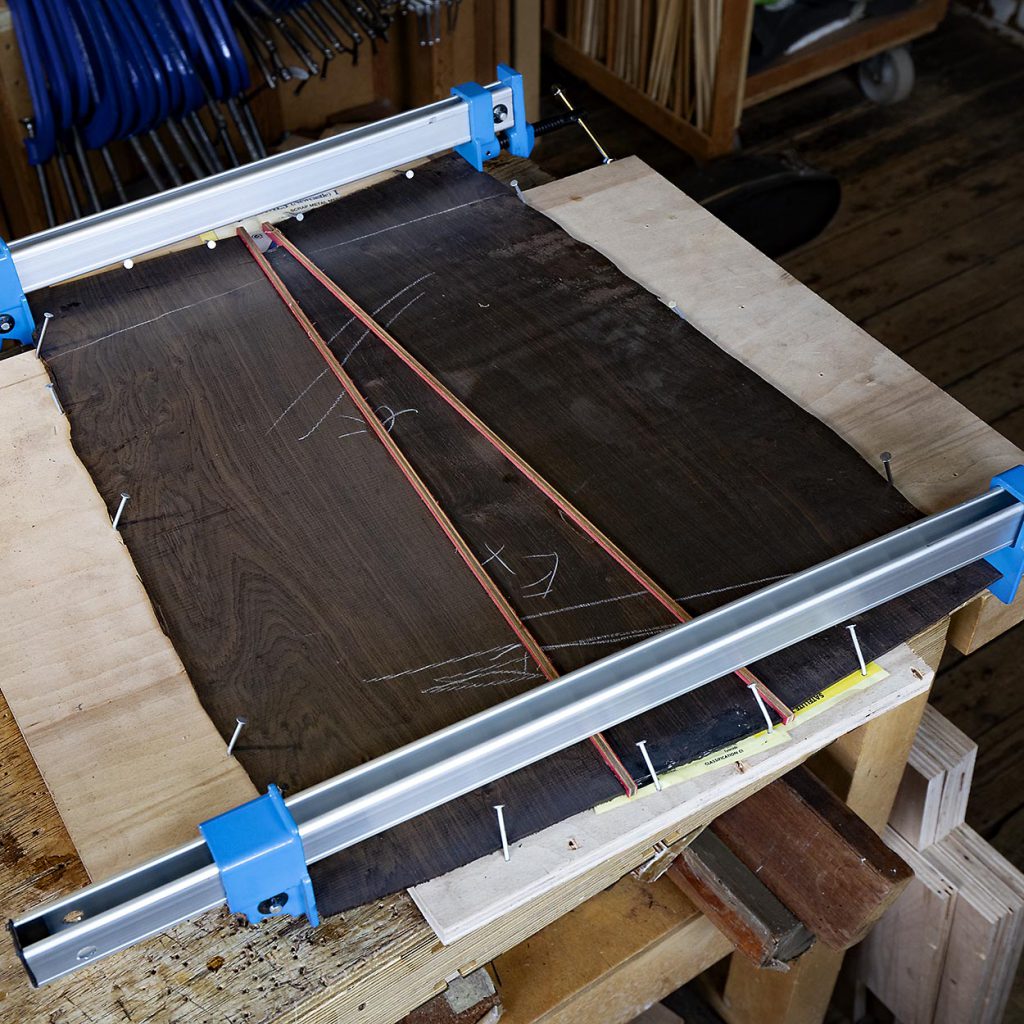

Today I fitted back braces to the Verona model I’m building. Left is the back with reinforcement struts cut away to receive braces, right the braces are glued and clamped in the go-bar jig. The back is placed in a mould which has the same radius as the curve I’ve shaped the braces to.

Incidentally, behind and to the right of the go-bar jig I store some of the different purflings and bindings I use.

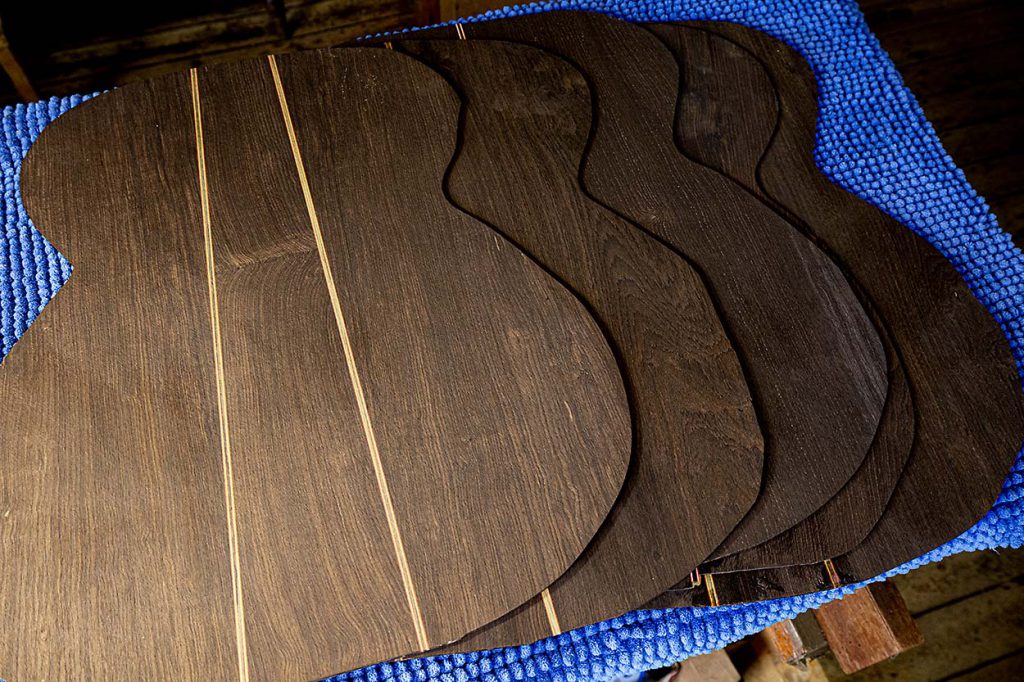

Sorted into sets. The 12 sets offered for sale are in the right hand stack.

Sorted into sets. The 12 sets offered for sale are in the right hand stack.